Model No.: GJ-1000

Brand: Helper

Voltage: 380V

Customized: Customized

Automaticity: High Automation

Type: Line Cutting Separating

Packaging: Seaworthy wooden case

Productivity: 65m per minute

Transportation: Ocean

Place of Origin: China

Supply Ability: 5 set per month

Certificate: ISO9001-2008, CE

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF,FCA,CPT,CIP

Linked Sausage Separator

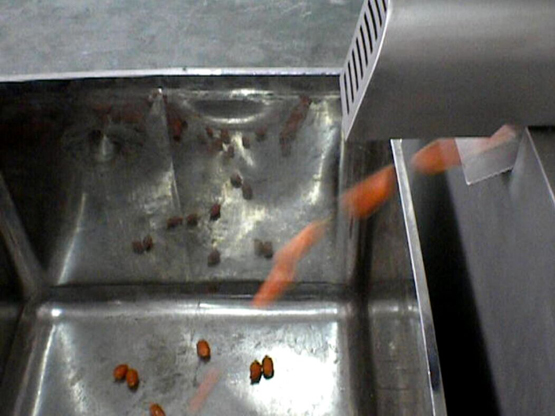

The machine is a kind of high speed cutting equipment which is developed independently by Helper Company for all kinds of twisted sausage. The cooked sausages pass through the tunnel quickly, and at the same time the optoelectronic sensor detect the sausage link point, and then the blades cut precisely at the right position according to the detecting signal. The sausages move synchronously with the conveyer belts, and this is the key point that sausage is clamped between upper and lower belts. Accurate guidance from the feed and discharge belts and precision cutting by the blade at the exact link point lead to extremely good cutting results.

Features and characters

--- adopts servo control system, running accurate and reliable.

--- High speed,maxmium speed is 65m/min.

--- Being applicable to sausages with different diameter and length.

--- Length of products can be detected automatically.

--- It can scissor casing products such as collagen casing, natural casing,ect.

--- Easy handle,controlled through the programme,operate with touch screen.

--- Safe and good mobility.

MAIN TECHNICAL PARAMETERS:

Dimension: 1500×500×960mm

Power: 2KW

Voltage: 220V

Speed: 500-1600 pellet/min

Least length: 30mm

Casing diameter: Ф13~Ф32

Product Categories : Meat Processing Machines > Filling And Linking Technology