Model No.: GN-1200II

Brand: Helper

Automaticity: High Automation Level

Casing Available: Natural Casing And Collagen Casing Etc

Application: Hot Dog Sausage And Twisting Sausage

Packaging: Seaoworthy wooden case

Productivity: 1200 pcs per min

Transportation: Ocean

Place of Origin: China

Supply Ability: 3 sets per two month

Certificate: ISO9001

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF,CPT

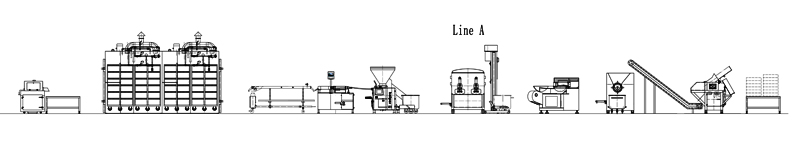

Taiwan Sausage Production Line

Introduction of Sausage Hanging Line

This machine was developed by our company in 2010. It consists of filling part, twisting part, length-control conveying part and tube-switch part, hanging part. It is suitable for various casing, such as collagen, polyamide or cellulose casing, etc. The double filling tubes structure is to fix casing at a filling tube at the same time when other filling tube is working.

Compared with traditional twister, it has the characteristics of high speed, continuous work, short auxiliary time and low waste of casing and raw materials. Because of its unique way of working, the quantitative error is very small in actual production.

Features and characters

--- adopts servo control system, running accurate and reliable.

--- high automatic design with precise hanging of the product..

---Double filling/twisting tubes structure to simplify the casing replacement.

---Twisting length and twisting circles are stepless adjustable.

---Connected with automatic hanging machine easily

---Stop running when run out of casing.

---Operation language is customized according to requirements.

--- Hygienic design concept.

Film of Linked Sausage Production Line

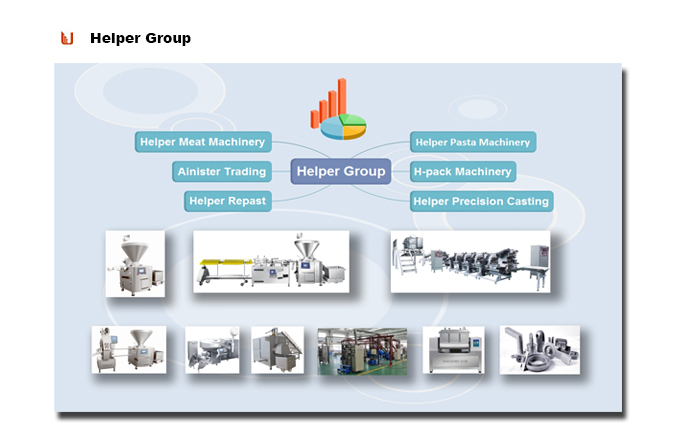

Product Categories : Food Processing Solutions